[warehousing management] - --- picking road length

- 2018-04-16 13:40

- Storage management picking and sorting optimization and integration

To that thing (warehouse operation index - picking path length) has been done a brief introduction on the origin of picking a long road. At the same time, the importance of shortening the length of picking is explained by data. Now let's talk about how to shorten the picking time.

The picking line length is the distance when the warehouse personnel pick up the goods from the start of each picking, to the completion of each order picking, and the distance it needs to walk in the warehouse, that is, the distance.

It is well known that the journey = speed * time

According to the formula, the factors that affect the picking length are picking speed and picking time. Therefore, if we want to shorten the picking time, we must start with these two points.

The speed here is actually the efficiency of picking.

The efficiency of picking is not just a simple factor of physical strength. It also includes important conditions for picking path design, optimization of Library location and so on.

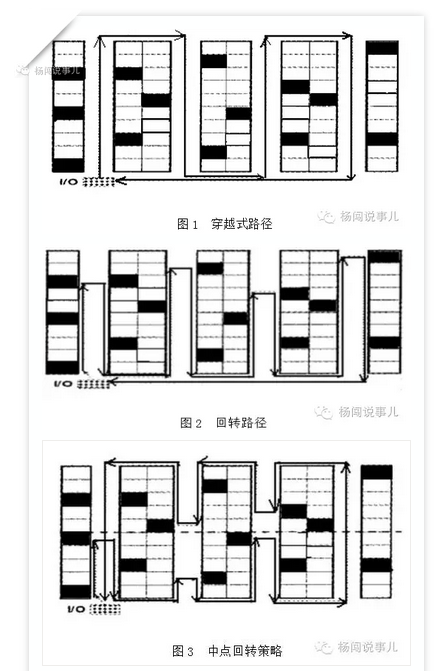

The optimization method of picking route refers to how to enter the next channel in the most shortcut way after a passage is finished, and how to pick up which is the same passage after entering the next channel, which can be picked up, thus reducing the invalid round trip.

For example, the following kinds of picking paths are:

Picking path design is directly related to picking length. Choosing the best picking path plays an important role in improving the overall efficiency.

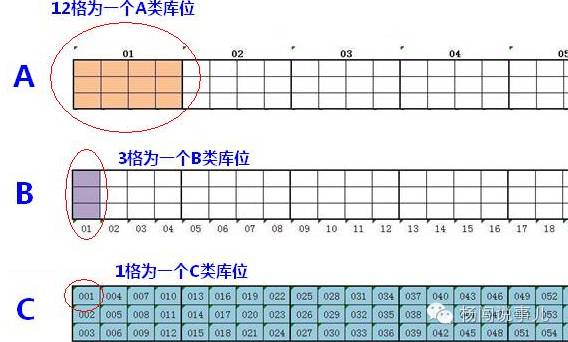

The optimization of library position is the factor that affects the picking personnel. Whether the design of storehouse is reasonable or not determines the destination of the picking personnel. Therefore, the optimization of the library position has a great influence on the picking.

The operation of Library bit optimization should start from the following points:

A will give the high frequency picking gold region goods, thereby maximizing the picking efficiency and minimize the cost of picking.

B distributive goods are evenly distributed in different picking areas to avoid congestion in a certain area, improve the working process, and shorten the total response time to a batch of orders.

C similar products should be separated, in order to reduce the chance of picking the wrong.

The commodity correlation is often ordered at the same time when ordering, so it should be stored in the adjacent position as much as possible. Can shorten the picking distance, reduce staff fatigue and simplify inventory.

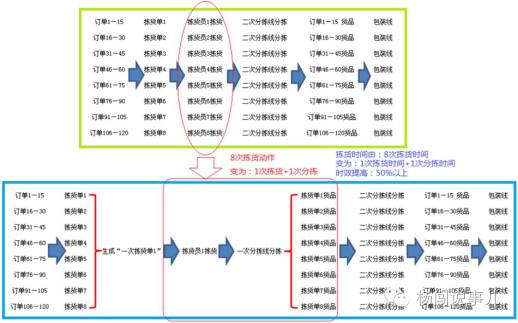

The re integration of the order order

More than one order task is merged into the same batch to be allocated by a pick clerk.

Summary

No matter in picking path, sorting location or order integration, it will affect the picking efficiency and shorten the picking time. Generally speaking, every step of warehousing will play a good role in the later stage.