Wang Zujin: network layout operation and intelligent development direction of logistics center

- 2018-03-23 14:07

- Logistics center network intelligent supply chain Internet big data

Editor's note:The layout planning and operation mode of the supply chain logistics network are highly related to the business model and the requirements of the service target. In the new economic environment, the traditional supply chain logistics network boundary has been opened. Intelligent information technology will help enterprises build an open and collaborative agile supply chain logistics network system.

The extensive and deep application of Internet technology and big data technology brings about two characteristics of business environment, the satisfaction of extreme personalized needs and the integration of dispersed demand. First of all, the marketing of enterprises becomes very fast and efficient, personal social network has been hitherto unknown development, the result is to-C's business model was a huge success, but the characteristics of the individual consumer's more liberal / fashion / leisure / personalized, more accessible to new brands and new services. Corresponding to the B side, the market demand structure is changing rapidly, and the market demand prediction is more difficult. The enterprise supply chain logistics network planning is facing the challenge of uncertainty.

Secondly, in the to-b field, information technology is helping to achieve integration to meet the previously dispersed needs of the enterprise and improve the purchasing efficiency of the demand side. At present, B2B supply chain platform mode is booming, the B side of the enterprise, facing the organization of supply chain planning more product lines and large amounts of SKU, compared to the logistics distribution network of the logistics network layout and operation mode with the traditional single enterprise own, the service function and order fulfillment mode are very the difference.

For the B2C logistics network layout planning, layout according to the number of outlets mainly from the customer demand distribution and customer order fulfillment time (order lead-time) to meet the rate of goal setting, can be a total warehouse services nationwide, can also be a number of regional warehouse services multiple areas. A more rapid order fulfillment rate requirement will drive more regional warehouse layout, or use a faster transport and distribution model.

On the other hand, the pursuit of the C end customer experience, especially the development of fresh electricity, has led to the continuous development of line and line integration service mode. Under the impact of e-commerce retailing, traditional retail enterprises have launched a passive transformation. For example, the process of the transformation in the electronic commerce Bailian Group, I was responsible for the integration of logistics development strategy planning, witnessed the determination difficult and business leaders the transformation process of traditional retail business of large. The traditional retail store facilities and resources is no longer just retail facilities, but has become a variety of functions under the mode of implementation of new retail consumer shopping experience one of the most important community service outlets; store service personnel from the pure retail function to retail services and online orders to perform operations personnel and terminal service personnel. Here, the traditional supply chain logistics network layout structure framework and the boundary is completely open, information technology + network facilities function transformation, help enterprises to construct the logistics network service platform open extension type, upper and lower inventory is open, network facilities resources are more participants sharing a variety of order fulfillment mode by means of the platform realization of open type city new retail and supply chain logistics network integration service platform.

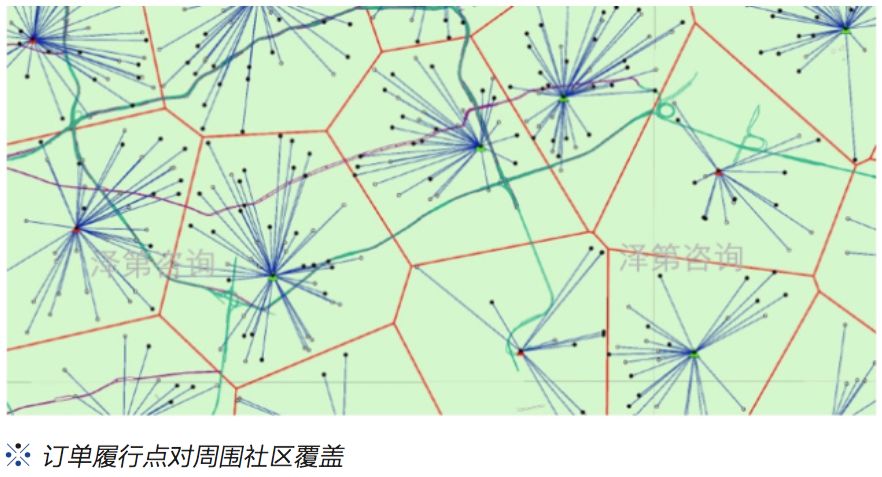

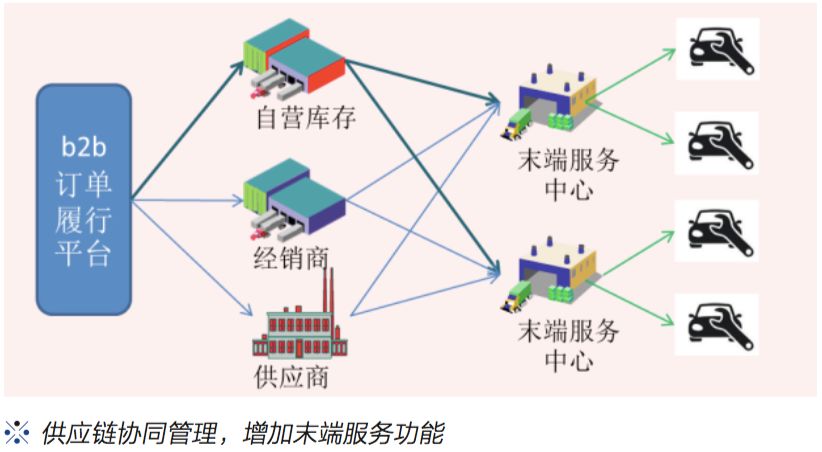

For B2B platform logistics network layout planning, there are many driving factors, including the complexity of product categories, huge inventory SKU, inventory management strategy, customer service requirements, and procurement distribution. Influenced by the supply of product categories, the network layout may move towards the model of the regional warehouse + category total warehouse. In the aspect of inventory management, in addition to the stock of its own network, it may also include the inventory management of some suppliers. In order to meet the needs of the end customer service from the strategic level, may require a large amount of terminal layout of regional service outlets, the number of possible from dozens to hundreds, at this time, the development mode of end of the network has become the focus of open cooperation will be conducive to enhance the strategic flexibility of enterprise logistics service network.

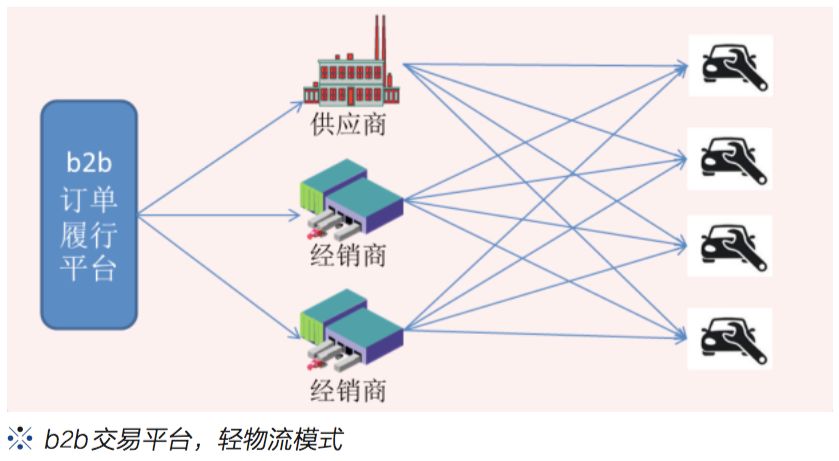

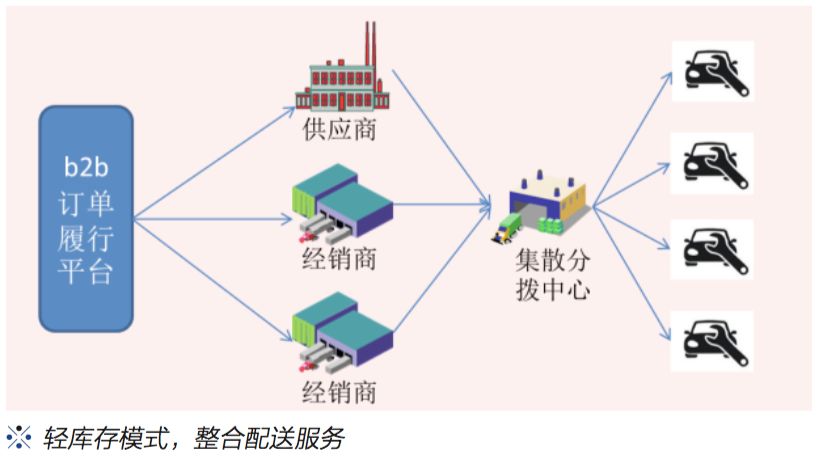

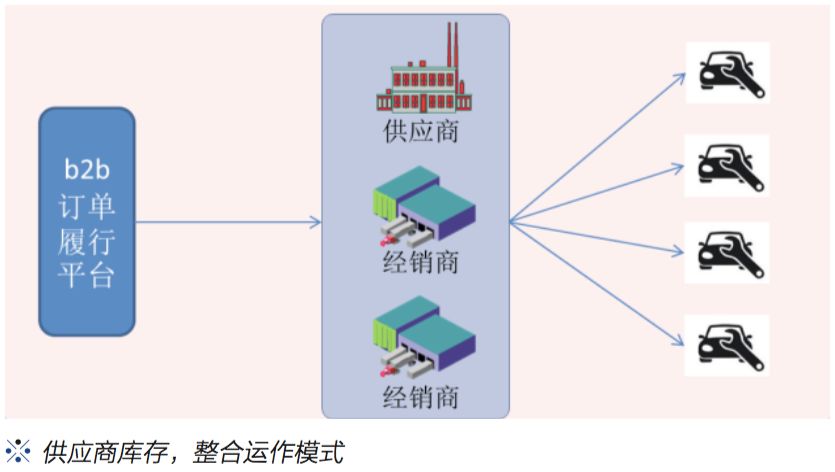

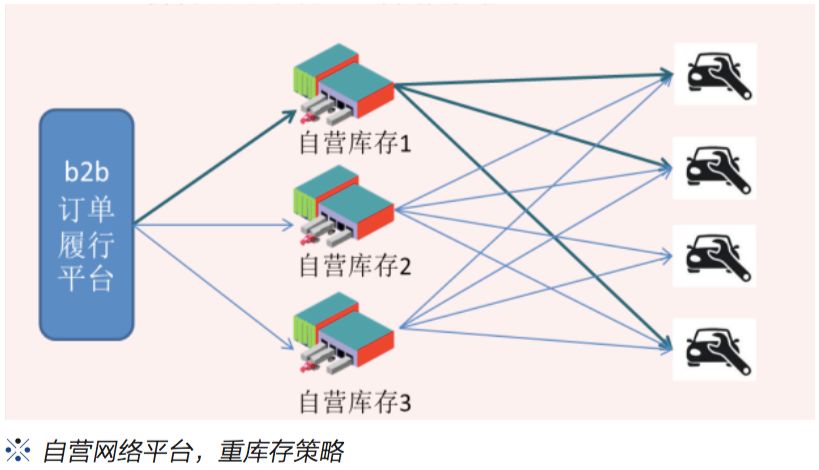

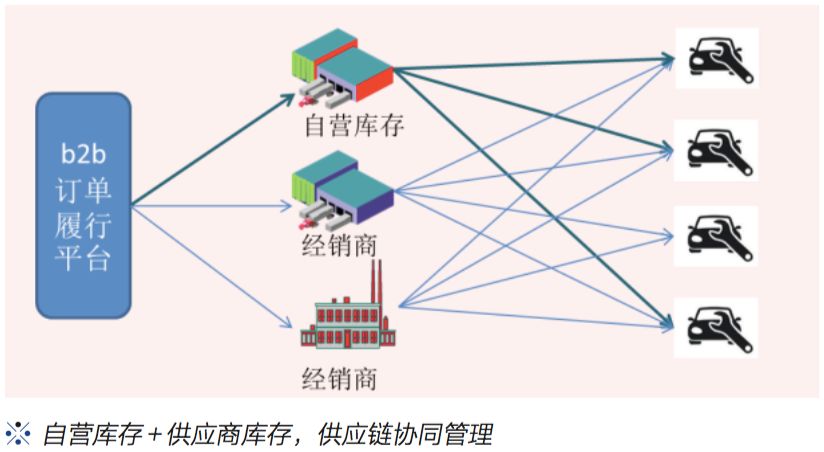

In recent years, the development of auto aftermarket accessories supply chain logistics network is an integrated service B2B supply chain logistics service network platform. The standard parts and complex vehicle parts are served to the terminal maintenance customer through the network platform. ?The key point of the plan is the order fulfillment mode in the supply chain. Different order fulfillment modes can be achieved through different inventory management modes, network inventory deployment strategies and terminal nodes' allocation and distribution services. There are a variety of model choices, which are highly related to the business model strategy selecion, and the focus is on the inventory management model and deployment strategy. The risk of an enterprise is also the same.

Inventory deployment strategy is the key and difficult point of logistics network planning. It is also the difference between different enterprise logistics network layout and operation mode, which affects the overall operation efficiency and operation management level. Inventory deployment strategy decision-making, including brand strategy dimension, product category dimension strategy, especially different brands or types of products supply distribution driven inventory deployment strategy; inventory also includes SKU products / goods / product structure characteristics of slow and fast goods tend to disperse layout, improve the order fulfillment time, slow goods tend to centralized management, improve order fill rate.

For the B2B platform, a large number of SKU (such as auto parts industry, building materials industry, and industrial products), slow stock inventory management mode and deployment strategy are related to the operation efficiency of the logistics network, but also accompanied by great risk, and even lead to business difficulties. This will need to consider the construction of cooperative / open type supply chain logistics network, in addition to self enterprise network facilities layout, also need to consider the upstream suppliers to the whole network facilities includes network layout, build a more collaborative supply chain logistics operation system and cyber source using proprietary inventory and supplier inventory. It is also necessary to consider the mutual cooperation with the facilities resources of regional service providers at the end of the wider market to build a highly flexible terminal service network.

The main traditional supply chain logistics network is relatively closed, but in the age of the Internet today, the business model, marketing strategy and service category has undergone great changes, or to cover the big development, will be greater; or to the depth of mining services, construction services made irreplaceable. Therefore, we are deeply aware that the supply chain logistics network in the Internet age must be open and must be synergistic between the upstream and downstream. only open, in order to achieve the extension of the service, in order to build a service function, need the capacity and service level, in order to achieve the strategic flexibility needed; only in order to maintain optimal coordination, to achieve the overall production, inventory and operation process of supply chain network, achieve a sustainable win-win development pattern.

The structure of the logistics network is called the "open and cooperative supply chain logistics network". In addition to the planning of the physical network layout and construction operation, more need to rely on the information system, from the purchase management, inventory management, order fulfillment management, operation management, warehousing, transportation and distribution management to the whole supply chain network operation management information system visualization, need professional support and coordination plan and specific operation, the optimal system efficiency to build win-win the operation of the supply chain network.

However, the implementation of the basic information system does not mean that the ultimate goal of open collaboration can be achieved. In the field of supply chain, information technology has come to the front from the basic technology facilities of enterprise operation and operation, and the open collaborative supply chain logistics network relies on intelligent information technology to achieve. The focus of supply chain collaboration lies in the timely transmission and acquisition of information, and the most important thing is to respond quickly and promptly. The traditional information technology focuses on information management and transmission, but the related response, decision and execution depend on the artificial realization. Supply chain collaboration involves many parties. All systems that require artificial coordination decisions are inefficient, at least unreliable (unstable), and difficult to achieve fast response collaborative goals.

For intelligent application of information technology, what we most anticipate is part of collaborative planning, decision-making and adjustment in the daily activities of supply chain. The implementation instructions can be completed by information system, that is, information machine instead of manual completion. It involves inventory management, inventory SKU deployment strategy adjustment, inventory replenishment, customer order fulfillment mode, transportation management, terminal service resource management, and upstream production plan organization.

The realization of the above system will ultimately lay the foundation for the agility of the supply chain logistics network. The concept of agile supply chain has been put forward in the 90s of last century. However, if the decision system of traditional supply chain logistics still depends on artificial decision-making, the agility of supply chain is impossible. Today's information intelligence technology and the development and application of large data provide basic technical support for the construction of agile supply chain. The core of agile supply chain is to respond to market demand, environment change, competition environment change and supply chain organization change timely, and its goal is to maximize customer satisfaction and reduce inventory.

Another driving force for the intelligence trend of information systems is the failure of the traditional demand forecasting system. Under the traditional business mode, demand forecasting is very important. based on this, enterprises carry out all kinds of business planning, supply chain logistics network system, according to product sales plan and supply plan to plan, and related logistics capacity planning preparation. In the Internet business environment, consumer demand is fast switching, and demand forecast is very difficult for enterprises and even meaningless for some industries. On the contrary, the enterprise development planning based on the development of relevant planning of supply chain logistics system in the actual operation, to the change of market demand, the supply structure changes and enterprise sales based on the actual situation, make corresponding adjustment, to maximize meet market demand, while maintaining the inventory investment as small as possible. These goals rely on information intelligence technology to help achieve the agility of the supply chain network operation.

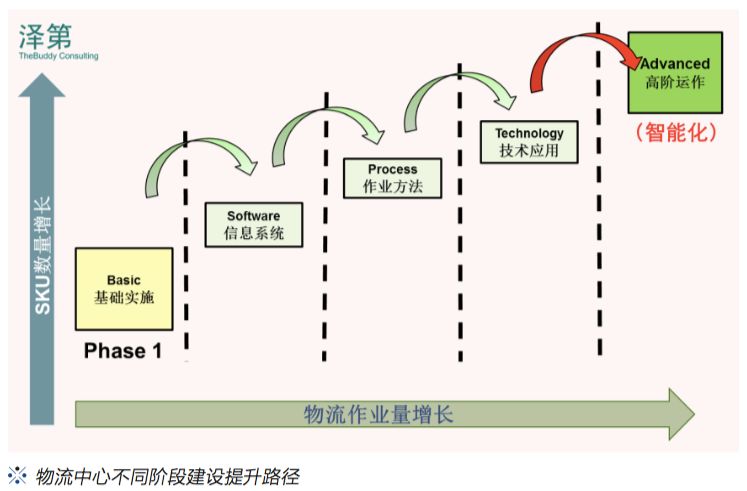

In addition, the application of intelligent technology in the operation environment of logistics center is also expected. In the development of the past more than 10 years, the domestic logistics center has modern logistics infrastructure and technology application, the warehouse operation management information system implementation, operation mode and process optimization, automation technology application stage, operation level has been greatly improved. Although the operation strategy and optimization of conventional ways to improve obviously, but also some common problems facing most of the logistics center daily operation, including how the storage layout optimization to improve work efficiency, how to group on the orders of different structures of the corresponding operation slightly improve the efficiency of order fulfillment, how to develop strategies to improve the overall replenishment operation how to realize the material handling efficiency, minimize the number of the completed order fulfillment work, how to improve the inventory turnover rate, to achieve continuous operation and reduce the waiting time for large space storage facilities to effective allocation of human resources, and the early warning system and visual management etc..

Under the Internet environment, the operational challenges of logistics centers mainly come from the increasing number of SKU, the changing structure of customer orders, and the increasing demand for timeliness of order fulfillment. The direction of construction of intelligent automation technology application is not, nor is the information automation, it should be replaced by the decision mechanism of machine learning and artificial optimization to make optimal decisions and daily operation of automatic arrangement to perform operations, to realize the strategy and operation strategy of the optimal, optimal resource utilization. The information technology supplier should help the customer to carry out the relevant practice in these fields and promote the intelligent development of the logistics center.

In a word, the layout planning and operation mode of the supply chain logistics network are highly related to the business model and the requirements of the service target. In the new economic environment, the traditional supply chain logistics network boundary has been opened. Intelligent information technology will help enterprises build an open and collaborative agile supply chain logistics network system.

In traditional thinking, the order of the construction and upgrading of the logistics center is from mechanization to information, operation process optimization, automation, and finally to intelligent. This order is unreasonable. In fact, informatization is the foundation of modern logistics. Intellectualization is the advanced stage of informatization. Regardless of the size of the logistics center, whether or not the automation equipment is applied, we should carry out the application of intelligent technology, so as to achieve efficiency improvement.

Wen and Wang Zujin